Freund-Vector’s Gf-215 Granuformer Displayed at Interphex Japan

The solid dosage pharmaceutical industry is subject to increasing pressure to control the growing cost to manufacture and deliver new products. As a result of these pressures, pharmaceutical equipment manufacturers are working with pharmaceutical companies to find ways to increase capacity, efficiency, uptime and utilization. Over the past decade, there has been a stronger emphasis placed on defining an alternative to batch processing.

What is that alternative? Let’s begin with defining batch processing and continuous manufacturing. Batch processing is, “sequentially loading a set amount of material, processing that mass, and then discharging all of the transformed material.” In comparison, Continuous manufacturing “involves material constantly being loaded, processed, and unloaded without interruption.

See Paper: Current Recommendations for Implementing and Developing Continuous Manufacturing

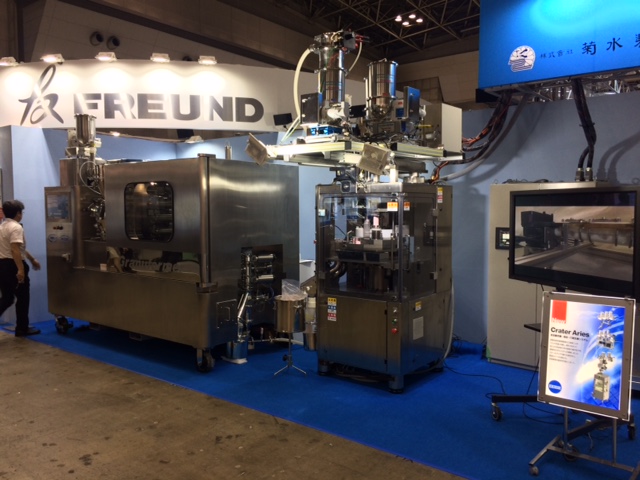

During Interphex Japan 2017, the Freund Group demonstrated continuous manufacturing with Freund-Vector’s Granuformer Gf-215. The Gf-215 was connected to a Kikusui tablet press and live presentations demonstrated the complete continuous granulation process from raw materials to finished tablets.

To learn more about Freund-Vector’s GF-215, visit Freund-Vector’s YouTube channel.